|

UK Sewage Treatment Requirements for Houses not Connected to Mains Drainage |

| If you have a house in the countryside, away from any

towns

or villages, it is usually not possible for it to be connected to the

Local Authority mains sewage system. This means that you will probably

have a septic tank, a small sewage treatment plant, or a cesspool.

Traditionally, such water treatment methods result in ponds and

soakaways containing foul water or, worse still, direct discharge of

foul water into streams and watercourses. This unsatisfactory situation

has been tolerated for a very long time, primarily because it was once

permitted and there was no great impetus to do anything about it. That

situation has changed however since the publication of new rules

governing sewage processing in small installations. These are outlined

on the following Government website: The following DEFRA document is also helpful in defining the various types of installation: The new rules essentially require that there must be no pollution, and hence no discharge of foul water whatsoever. It is also necessary to keep records of the measures taken to ensure compliance. This is a considerable departure from what had prevailed earlier, and the upgrade of installations to meet new regulations became mandatory in January 2020. Up until late 2020, there has been no enforcement action taken by Local Authorities in respect of domestic installations, but that situation is likely to change. Furthermore, any works carried out at the property are likely to trigger Local Government scrutiny and, as many have found to their cost, the property is rendered unsaleable until compliance is achieved. |

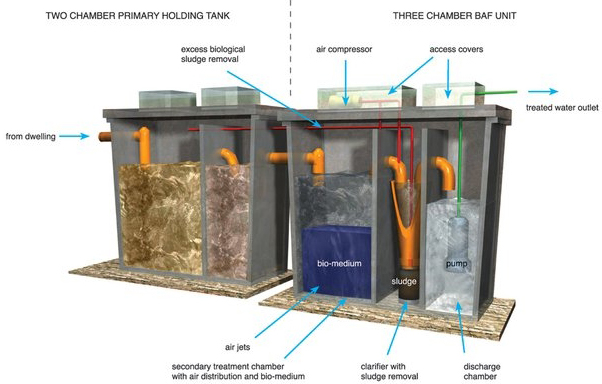

| East Island Farmhouse We bought East Island Farmhouse in 1995, and the sellers drew our attention to a section in the deeds permitting us to discharge septic tank runoff into a stream running alongside the property. That situation however was not always to the liking of our next-door neighbour a little further down the hill, and it made one corner of our garden smell disgusting. We eventually came to restrict the number of people allowed to spend long periods on site, and we arranged to have the septic tank empted more frequently than we had previously given to believe would be necessary. That policy, albeit unsatisfactory, prevailed for many years; but when the new environmental legislation came into force it became obvious that we would need to comply with it as quickly as possible. We expected that such compliance would prove expensive, but we were nevertheless looking forward to the benefits of having a clean watercourse and happy neighbours. While we deliberated on what to do, it so happened that two of our business-owning neighbours were in the process of having large commercial systems installed. The works in both cases were contracted to a company called 'Leach Brothers Ltd.,' and entailed the installation of sewage processing plant manufactured by O'Reilly Oakstown Environmental; Since the installation teams were working nearby, we were able to get both Fred Leach and Diarmuid O'Reilly to visit our site without the need to make special arrangements. We thought that they might not be impressed by our somewhat small-scale requirements, but they were perfectly happy to assist. We eventually opted for an Oakstown BAF (Biological Aerated Filter) system classified as 10PE (10 population equivalent) under the Irish and British Agrement certifications, tested as 8PE under the European norm En12566-3, and classified under UK regulations as suitable for a property having 5 bedrooms and 7 permanent residents. A diagram of the BAF system is given below. It requires an electricity supply for the aeration compressor, and since it is a wet system, this has an RCCB. The power consumption is very low however, and the feed to the RCCB can be plugged into an ordinary household power outlet. |

Diagram copyright: O'Reilly Oakstown Environmental.

| We were shortly given a very reasonable quote and asked for

the work to go ahead. Some photographs of the excavation and the

installation of the concrete tanks are given below. |

Groundworks.

Tank delivery lorry.

Lifting the Oakstown BAF aerator tank into place.

Final tank positioning prior to connecting electricity and pipework.

| Commissioning involved diverting the soil pipe from the old septic tank, taking the new outlet to the stream, and switching on the electricity. We then got our usual septic tank emptying contractor, ABBA cleansing, to empty the old tank and inject about 1 m3 of the sludge into the first chamber of the new tank. The reason for doing so was that the old tank had a well established bacterial culture for breaking down solids, and the material would therfore get the system going. Finally, the old septic tank was broken-up and taken away for dumping in a field that we have above the property, and much of the spoil heap from the new excavation was put into the vacant hole. |

| Protecting the bacterial culture A septic tank is a living biological system, and as such can be put out of action by toxic chemicals, fats and oils. A small amount of cooking oil does not do much harm, and can be emulsified by SLS and SLES (washing-up detergent and shampoo), but solidifiable fats should be collected and put-out with the landfill waste. Petrol, Kerosene, and engine lubricating oils should be kept out of the household drains at all costs. East Island Farmhouse has an ancient and somewhat decrepid swimming pool containing 160 m3 of water. When we bought the house, the backwash and drain outputs from this pool were put straight through the original septic tank, and sanitisation of the water was by means of chlorine. This terrible arrangement would, of course, have been lethal to the tank and made the house a serious source of pollution. One of the first actions on taking over the property therefore was to divert the pool output directly into the stream; bearing in mind that pool discharges are intermittent, and farm slurry would have been the greater problem at the time. A few years later moreover, the pool circulation system was rebuilt, and the diabolical chlorinator was replaced by a UV steriliser. Thus, the output from the pool is now not much different from potable water. The sheer volume of water discharged during backwashes, and particularly during pool emptying (a mercifully rare event), would nevertheless have washed-out the tank and disrupted the culture had the pool still been feeding water into it. DWK 2020-11-19 |