|

Underwater housing care

What is the correct O-ring grease to use with a submersible housing?

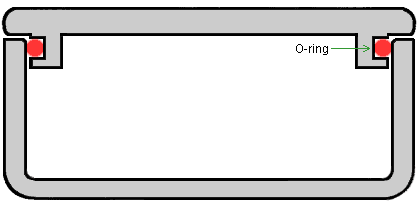

There are two basic configurations for O-ring seals; the `Piston' seal, and the `Gasket', or compression seal. In the former, one part of the assembly slides into the other, while in the latter, the O-ring is squashed by a lid. The back doors of many compact camera housings have piston seals. The back doors of many SLR housings have gasket seals. O-ring grease is not a sealant; it is a lubricant that enables piston seals to be assembled without damage. Consequently, gasket seals do not need grease, although a light coating may help to preserve the rubber and may assist in cleaning.

|

Piston seal |

If grease is required, the type used is very important. In the past, housing O-rings were nearly always made from Nitrile-Butadiene Rubber (NBR), usually black, and the appropriate lubricant is either petroleum gel (i.e., Vaseline), or preferably Silicone grease (e.g., Molycote 111).

Nowadays, Silicone O-rings are common. These are often coloured, and can be recognised by their textural similarity to silicone diving masks. Petroleum gel can be used on some silicones, but silicone grease will migrate slowly into the material, causing it to swell and possibly disintegrate. The correct lubricant for silicone rubber is fluorosilicone grease (e.g., Molycote FS1292).

It is also important to distinguish between user seals (like the back door of a housing and the battery cover of a flash unit) and control shaft seals. User seals and static seals need only to be greased before assembly, but control shafts need to be packed with lubricant. If you simply grease a control shaft seal, it will soon dry out and fail through abrasion.

How much grease should you use?

For O-rings, the grease helps to loosen dirt and acts as a preservative. Put a small amount of grease on the O-ring, spread it around, and then wipe off any excess with a lint-free cloth or paper towel. The O-ring will be left with a thin coating of grease. This is generaly sufficient. Surplus grease simply acts to collect dirt.

Silicone grease can also be used on screw threads, such as the camera tray and flash arm fixings, to reduce corrosion and promote smooth running. In that case a fairly generous amount is warranted.

How often should you service your housing?

User servicing should be done before and after every dive. It is also advisable to do it as close to the dive as possible. Before every dive; you should check and clean the main back-door O-ring and the O-ring groove, and check that everything is functioning correctly. After every dive; you should try to rinse the housing and anything that has been attached to it in fresh water as soon as you can.

When two different metals are in contact in salt water they form an electro-chemical cell (like a battery), where an electrical current flows and one of the metals dissolves. Severe corrosion occurs in places where water remains trapped in contact with metals when the equipment otherwise apears to be completly dry. For example, a brass or stainless screw in an aluminium socket will have water trapped in the threads. There are two ways to prevent corrosion in this situation: either, take the screw out after diving; or, cover the threads of the screw in silicone grease before putting it in. The second choice is best when attaching, say, a mounting ball to the top of a housing; since the need for repeated dismantling of permanent fixtures is an inconvenience. Greasing the screw-threads of hand-assembled parts (tripod screws, connector nuts, etc.) is also a good idea. The first line of defence against corrosion however, is to remove lighting trays from housings, dismantle ball arms, unplug electrical cables and cap them off, etc, prior to storage.

DWK

DWK