|

|

|

Pantograph engraving machine |

|

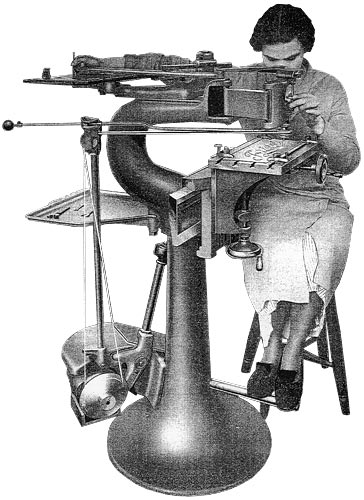

The Taylor-Hobson pantograph engraving machine, once commonplace

in engineering works throughout the UK, has now largely been

superseded by low-cost panel-marking techniques, such as screen-printing,

or by the use of engraving cutters in CNC milling machines. A

consequence of this obsolescence however, is that the machines

change hands for amounts of money quite disproportionately small

in comparison to the quality of the engineering. Shown on the right is a model CXL. This is the largest of the C-series, having a bowed main casting to accommodate large panels, and a 14" vertical slide to allow the use of dividing heads and other large accessories. The basic pantograph ratio is continuously adjustable from 1:2 to about 1:30; and the cutter is driven at speeds up to 15000 rpm by a long belt with jockey pulleys (like an old-fashioned dentist's drill). The machine is also provided with a cutter-grinding attachment (not shown), which fits on the machined and keyed area on the main casting and is operated by re-routing the cutter drive-belt. |

Taylor-Hobson CXL (Last manufactured in 1959). |

Taylor-Hobson CX Note the shorter vertical slide in comparison to the CXL. |

When used for its intended purpose, the

machine is an ergonomic masterpiece. There are few machine tools

that put everything to hand and allow the operator to adopt a

comfortable position, but this is one. The operator can sit on

a stool and use a protruding bar and the motor housing as footrests.

The cutter is raised and lowered by a knurled handwheel just

above it, operated by the left hand. The right hand moves a metal

stylus over the copy table, on which letter templates and other

artwork can be clamped. A tray, attached to the main casting

(above the motor) is also provided for tools and other small

accessories. The engraving of metals normally takes place under a puddle of cutting oil or kerosene, and the chips produced are too small to escape from the oil. Hence the swarf is removed when the workpiece is wiped or cleaned. |

|

Above: Right: |

|

|

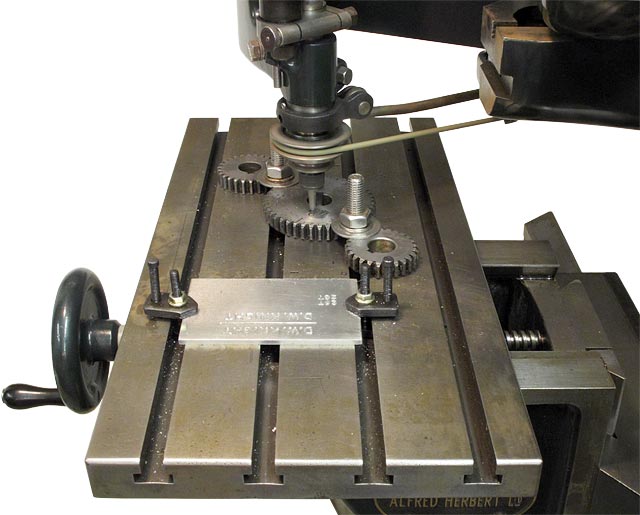

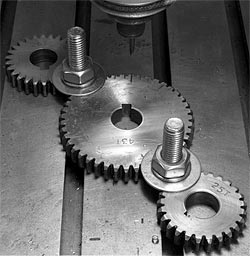

For those who can find no obvious use for an engraving machine

of this type, it is worth noting that it provides a superbly

engineered 3-axis universal table, for a secondhand cost that

is less than the normal price for a 2-axis table. Also note that

the pantograph assembly is easiliy removed, and it sits on top

of the main casting on a flat sliding bed that is precisely machined

parallel to the work table. This means that the machine is easily

converted into a vertical milling machine or (with some measures

to cover-up the lead screws and slides) a surface grinder, etc..

One feature it lacks is micrometer dials on the lead-screw handles. This can easily be remedied however, by anyone who owns (say) a lathe, a dividing-head and an engraving machine. The lead-screw pitch (of the CXL at least) is 0.2", which means that a dial of 40 divisions will provide a mark every 0.005" (0.127 mm). |

|

Web links: |

|

|

. Home << Workshop .